With almost every acid-stained and decorative concrete floor, there are going to be some kind of visible joints. Some of the joints are saw-cut; others are formed into the floor manually. Most of the time, the placement of these joints was planned and implemented before the floor owner decided to stain, or otherwise decorate, the concrete. Joints are an important part of every horizontal concrete floor. Most of the time, their purpose is to keep the floor from cracking. Because they are simply meant to keep the concrete from cracking, the joints usually stand out more than they otherwise would.

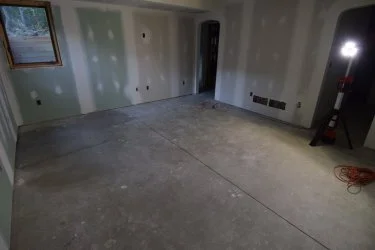

In this small basement, the joints in the concrete were placed before the walls went up. As a result, there is a large, noticeable joint in the middle of the floor.

As such, any seasoned and skilled decorative concrete flooring contractor will invariably suggest making additional saw-cuts to a floor owner so as to make the original cuts and joint symmetrical in the overall appearance. They also may suggest filling them with a colored material to make them complement the decorative nature of the floor, and facilitate maintenance. Less experienced contractors will use sanded or unsanded tile grout for this application. The problem with tile grout is that it scratches the concrete sealer when it’s pressed into the joints, and when the excess is wiped or removed from the surface with a sponge. Since it dries hard, and inflexible, tile grout also may shrink, and crack, over time, leaving a visible line right down the middle of the joint.

We made some additional saw-cuts in the floor, of the same width, to incorporate that joint into an aesthetically pleasing pattern.

Joint fillers and joint sealants don’t scratch the floor, or crack, and are a much better alternative than tile grout. When we first entered this business, we didn’t do a lot of saw-cutting, or filling of joints on our floors. Now, we do a little of it on almost every project. One of the main purposes of this article is to explain the differences between joint fillers and joint sealants. Most contractors don’t know the differences, and if you asked to have the joints in your acid-stained or decorative concrete floor filled, chances are you could get the wrong material and end up with joints that don’t look or function right.

If the wrong joint material was used, it could have a big negative effect on your floor. The material in the joints wouldn’t look or function the way it should, and it could be easily damaged in the course of the floor’s normal usage. It might come out of the joint. It might discolor easily. It might lose its shape or tear. We use both joint fillers and joint sealants. The joint fillers we use are from Versaflex and Metzger McGuire, and the joint sealant we use is from Sika. These are the three best makers of joint fillers and joint sealants. The main determinant in which to use on a project is the material’s hardness. Joint sealants are flexible and soft to the touch. Joint fillers are more rigid, and hard to the touch.

The concrete contractor that poured this garage floor made a bunch of saw-cuts around this sewer grate to keep the floor from cracking. It didn’t work because he didn’t incorporate an isolation joint.

With a larger joint, typically expansion and isolation joints, which mark a complete separation of the concrete from the material adjacent to them, you would use a joint sealant. Expansion and isolation joints are usually at least ½” wide, and encounter a lot of movement, due to ground settlement, or outdoor temperature swings, and you need a softer, more malleable material. Joint Sealants accommodate a lot of movement. They stretch, and don’t crack. With a smaller joint, however, like a contraction, control, or construction joint, you don’t need or want flexibility. You just want hardness, durability, and good adhesion, so you would use a joint filler. Joint fillers are generally at least semi-rigid in nature, and are not soft and malleable.

The hardness of joint fillers and sealants is measured by something called “Shore D”. Shore D is a measuring system for the hardness, and resistance to indentation, of “elastomers” and rubbers”, and you can typically tell by the number whether it is a joint sealant or joint filler. For example, a joint sealant, like Sikaflex 2C, from the Sika Corporation, has a Shore D hardness of 45, and is considered “flexible”. By contrast, a joint filler, like Spal-Pro RS 65 or 88, from Metzger McGuire, has much higher Shore D hardnesses, of 65, and 88, respectively, and is considered “semi-rigid”. In general, joint sealants go up to 60 in Shore D hardness, and joint fillers go down to 65 in Shore D. The Shore D numbers of joint sealant and filler also lets you know how flexible or rigid the material is, compared to common materials, like a mouse pad, inner tube, pencil eraser, tired tread, shoe sole, phone cord, or swivel wheel.

Here is a sample board with perfectly place joint filler in the middle. At the bottom of the photo are the color samples the customer chose from.

There are many other differences between joint sealants and joint fillers, as well, and you should know some of the basic ones, if you’re going to have an acid-stained or decorative concrete floor installed in your home or business. One of the most important is time for both of the materials to cure. Joint fillers are great, because they set up in a matter of minutes, and you don’t have to worry about the material being tacky to the touch, or the possibility of stepping on it and smearing it. Within an hour of the material being dispensed, it can’t be easily damaged or even affected by external forces. By contrast, joint sealants usually take 2 or 3 days to fully cure, and before that time, you have to protect the material from touch and moisture, usually by cordoning off the project area. Joint sealant is like syrup, and if it is touched before then, it’s very easily damaged, and can be difficult to fix.

In this acid-stained concrete floor, the saw-cut pattern is too small. Also, there is no border, and the saw-cuts were filled with white tile grout. In our opinion, the saw-cutting and tile grout ruins the floor.

Third, the joint sealants and joint fillers are fundamentally different in chemistry. Joint sealants are typically elastomeric polyurethanes, similar to rubbers, whereas joint sealants are elastomeric, semi-rigid polyureas, an entirely different compound, and harder material. One of the main ways this differing chemistry exhibits itself is that with elastomeric polyurethanes, there is a long application window. The material is two components, and once mixed, the material can be used for up to four hours before it has to be discarded. Polyureas on the other hand, set up very fast, in a matter of minutes. Because of this, the material comes in cartridges that mix upon being dispensed. You have to dispense the entire amount once you start, otherwise it will harden in the nozzle. Joint sealants, by contrast, are mixed with a drill and mixing paddle in a bucket, and then dispensed from a large single component caulking gun.

Both joint sealants and joint fillers require considerable training and skill to install, so your average decorative concrete contractor is not likely to offer this service. It’s messy, and requires precision to make the material look nice in a relatively narrow space, like a joint or saw-cut. They also generally cannot be found at big box stores, and have to be specially ordered. We work with customers at the outset of a project, usually during the onsite consultation, to determine whether or not to fill existing joints and saw-cuts, and what material to use. We also offer an extensive color range, and have color charts on our website. Once a customer narrows their color choice down, we will bring actual cured color samples for them to view in person.

These are actual cured color samples of Sikaflex 2C joint sealant. We use these on the job site with customers. It’s a much better product than normal caulk you would find at Home Depot.

In addition to this, most decorative concrete contractors won’t have a concrete saw, or offer saw-cutting in order to place additional joints and saw-cuts into the floor. The best a customer can usually hope for is to have existing joints filled with tile grout, or even concrete caulk, but concrete caulk is not the same as joint filler or sealant. Concrete caulk is much less durable, and it only comes in one color: gray. This means that whether the contractor you are considering offers saw-cutting, and joint filling or joint sealing, is something you need to determine at the outset.

Fourth, because joint fillers are hard, they generally go in saw-cuts or joints ¼” wide or less, where they effectively remove a disruption in the floor surface, and assist in what is called load transfer at the joint. This stability in the joint means that heavy weights like dollies, or fork lifts, will tend not to chip or spall the edges of the joint when they come in contact with joint filler. Joint sealants, by contrast, are not hard enough for joints in the middle of a floor. They are generally used in joints on the perimeter of a floor, or near large building elements, like columns, where the most important function they provide is resistance to water, not foot or wheeled traffic. These joints are usually much wider than contraction or control joints.

This is a polished concrete floor in Kroger. The joint filler is pulling away from the joint edges because the joints were filled shortly too soon after pouring the concrete. It’s obvious that the contractor didn’t take the project and application seriously.

These are the most important differences between joint fillers and joint sealants. The easiest way of thinking about these two materials is to consider the size and location of the joints. If the joints are in the middle of the floor and are relatively narrow, you’re going to want to just fill them. If the joints are bigger and wider, and really stand out, you’re going to want to seal them, for protection from moisture, in addition to filling them. We often use both types of materials on a project, and will match colors, so that they all blend in, and you can’t tell the difference between the two. Leaving joints and saw-cuts empty is fine, but filling them often looks much better, and keeps material from falling in and accumulating. Left empty, saw-cuts and joints will often fill to the top with debris.

For more about the filling of concrete joints and saw-cuts, see this section of our website: Concrete Joint Filling .