New two-story home being built on a beautiful wooded lot near Saugatuck, Michigan. The owners decided on decorative concrete flooring for the main level and consulted us about the best system.

One of the biggest questions homeowners face in choosing a type of decorative concrete flooring for their finished basement, garage, or other indoor living space is: "Should I go with acid-stained concrete or a designer metallic epoxy coating?" To adequately answer that question, the homeowner needs to determine more specifically, "What are the differences between these two flooring systems, and how do I know which one is best?"

Most residential and commercial flooring systems each have their own pros and cons, whether it's an upscale, or inexpensive, form of wood, tile, carpet or concrete. Some of the most important features and characteristics of indoor flooring systems include: durability, ease of maintenance, air quality, moisture resistance, pet friendliness, affordability, beauty, and VOC levels. No one system has it all, but examining the type of residence or business involved, and defining the specific function, or overall use, of the project space will usually help narrow the available options and identify the most suitable and appropriate choice.

Decorative concrete flooring with a high performance, chemical-resistant clear sealer is a common choice for hair salons. The flooring in this particular salon is a 3/8" self-leveling cement overlay colored with brown concrete dye.

Hair salons, for example, often opt for ceramic tile, or urethane and polyurea coatings and sealers, for maximum chemical resistance. In homes, carpet, luxury vinyl tile (LVT) and wood laminate are popular choices because of their premium styling, diversity of choices, and light, easy maintenance. As with wood, tile and carpet, there are also different types of decorative concrete flooring systems that offer the same conveniences: acid-stained concrete, polished concrete, warehouse look (matte gray) concrete, and colored cement overlays.

One of the newest decorative concrete flooring systems, first introduced in 1998, is called "metallic epoxy". Metallic epoxy is basically a traditional epoxy coating to which metallic pigments with 3D, iridescent qualities have been added. Due to its favorable reception, and almost instantaneous popularity, this new coating system by 2007 became adopted and marketed by most decorative concrete and coating manufacturers and retailers, with their own branding and unique, snazzy, "metallic"-related product title. Despite these superficial variances, metallic epoxies share the same basic traits: they are very thick (up to 1/8"), self-levelling, uniformly-colored epoxies into which metallic pigments of a secondary color are dispersed, in any number of "designer" patterns, after the coating is poured or spread out on to concrete floor.

The type of epoxy coating material used for this application - "100% solids epoxy" - has a very long set time, usually ranging from 12 to 24 hours. This long set time is necessary for the primary and secondary metallic pigments to fully utilize the independent forces of gravity and rheology so as to flow and settle out into the installer's desired, unique "designer" pattern. The secondary metallic pigments used with the colored, 100% solids, epoxy base coat are usually introduced into isolated, or limited, areas of the epoxy base coating only after it has been applied to the floor, and levelled. These pigments are then sometimes further spread around with the aid of paint rollers, squeegees, drops of denatured alcohol, and even mini leaf blowers.

Metallic epoxy coatings have become in a short period of time one of the main choices for decorative concrete flooring, along with acid-stain, for basements and garages in new custom homes. Premier Veneers is trained and certified by various manufacturers to install both of these systems, including the metallic epoxy products from iCoat Products, Rustoleum/Citadel, and Dur-A-Flex. We generally choose not to offer or recommend metallic epoxy to our residential customers, however, because unlike the various and many forms of wood laminate, luxury vinyl tile, and carpet, we generally do not believe it is a viable or legitimate form of "decorative concrete". The outcome is also often very unpredictable, much more so than acid stain, which can lead the customer to feel "this isn't what I expected".

Metallic epoxy installations, like this one, usually start with black primer to increase the coating's contrast with the floor, followed by a layer of thick, colored epoxy spread with a trowel. These coatings completely obscure the concrete beneath.

The main problem with metallic epoxy is that, rather than accentuate the concrete where it is being installed, it covers it up. As such, it is not really a "form" of decorative concrete, as much as it is a type of "decorative coating", or "faux finish". Metallic epoxy does have a certain artistic appeal, and it can look great in some situations and business environs, but in covering up and obscuring the concrete slab it is applied to, and with such a dense, thick and opaque layer, it eliminates all the benefits and aesthetic appeal of concrete as a natural building material.

Nevertheless, after a little more than a decade of widespread use, metallic epoxy remains the popular choice of homeowners for basements, garages, and other indoor concrete, because of its "similarity to acid stain", and because it has been widely and effectively marketed to homeowners and contractors as a "better, quicker and easier alternative".

This typical acid stain color chart shows the subtle, natural mottling effect of the naturally occurring chemical reaction between metallic "ions" in acid stain with calcium hydroxide in the concrete.

Metallic epoxy is thought to be similar to acid stain in that it normally consists of, and displays, a "naturally" flowing combination of two different colors - or at least two different "tones" of the same color. It is marketed as a "better, quicker, and easier" than acid stain because rather than painstakingly clean and preserve the surface cement of the concrete for the optimal application of, and reaction with, acid stain, the concrete can just be quickly ground clean with a handheld or walk-behind grinder, with no regard for damage done to the concrete, like gouges and swirl patterns, from the diamond blades and tooling.

In addition, rather than having to allow the concrete to dry overnight after each of the multiple stages of the acid-staining process - cleaning, staining, rinsing, sealing - you will often hear contractors boast that all metallic epoxy involves is "one thick application of epoxy after grinding and crack repair, and then we're done", and "we can do it in just one day".

The truth of the matter, however, is that these two systems are not all that similar in appearance, and metallic epoxy is really not a better, quicker or easier alternative. These statements are really just marketing ploys. Metallic epoxy has a whole set of problems uniquely its own, and acid stain really isn't the quirky, idiosyncratic and difficult system to install that it is made out to be.

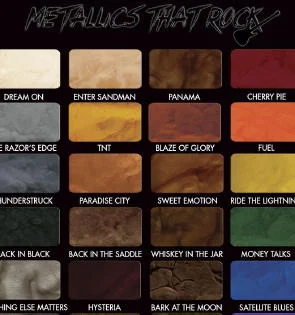

This attractive metallic epoxy color chart shows the dramatic, synthetic flow of color resulting from the gradual dispersion of colored metallic pigments in the self-levelling epoxy after application.

First, unlike acid stain, which chemically reacts with concrete to create the elegant and natural appearance of marble and other forms of stone, metallic epoxy has a much more synthetic look: it is simply a pigmented coating, and much of the metallic pigment used in the coating ultimately does not completely disperse as it should. It is normal to see small "comet streaks" of clumping pigment throughout the cured coating that look like they don't belong, and concentrated pools of pigments that have settled in low areas in the floor. On top of this, while these metallic pigments are eye-catching, they have an "iridescent 3D effect". The final appearance of the floor is not one consisting of natural layers and depth, as with acid stain.

Second, metallic epoxy doesn't always evenly disperse into a natural, flowing pattern across the entire floor, or even settle out in a consistent way. Sometimes, the 100% solids epoxy sets up more quickly than is expected, due to ambient conditions and/or modified manufacturer formulas, and consequently, the metallic pigments are locked in place after only partial movement - permanently reflecting and revealing the patterns by which they were applied, such as pouring out of a container, or spreading with a roller or squeegee. This problem can be made worse when contrasting colors are used together.

This faulty contractor sample board shows what happens when metallic epoxy sets up too fast: the metallic pigments don't settle out in a natural way, and permanent, unnatural and inconsistent patterns result.

Third, because 100% solids, self-leveling epoxy is placed at such significant thickness or depth, and in only one layer that takes a long time to set up, it is common to see a myriad of defects on the surface of the coating. For example: 1) pinholes from air trying to escape the concrete and/or coating; 2) small craters or "fisheyes" from contaminants like grease, oil and dirt; and 3) small irregularly shaped pieces of debris, like lint, fuzz, fibers and hair that settle in the coating due to air movement in the room. All of these defects interrupt and mar the continuous shine and gloss of the coating in an unsightly way.

Fourth, metallic epoxy is more prone to physical damage than acid stain. This damage is also more difficult to fix. The reason for this is the color and patterning is in the epoxy coating itself, rather than the concrete below, as with acid stain. When chips or flakes happen with metallic epoxy, the coloring and patterning are lost completely, and must be reproduced during the repair, whereas with acid stain, any chips and flakes normally occur only in the clear sealer, and not in the stained concrete below. The clear sealer over acid-stained concrete can easily be touched up or repaired, without having to reproduce any patterning.

This acid-stained basement concrete floor was installed by Premier Veneers in Barrington, Illinois in 2015, using a gold tone base with brown accenting and highlighting. The floor won acclaim in the decorative concrete trade as reflective of the best acid stain has to offer.

Fifth, metallic epoxy is much more susceptible to moisture problems. In its normal state, concrete is like a sponge, and retains a lot of moisture left over from the mix water used during placement. In a basement, below grade, or in a garage, where rain and snow easily intrude, this moisture level can easily increase to unacceptable levels. The problem is, metallic epoxy is so thick that it will not allow this moisture to escape. The thin sealers applied over acid stain, however, are generally breathable and help avoid any permanent damage to the flooring system.

By contrast, this metallic epoxy floor was installed by another contractor at a Michigan DNR office in 2017, using the same colors. Pigment pooling in low areas created an unnatural, unsightly and synthetic look.

All of the above problems can be compounded by an inexperienced applicator. But even with a skilled applicator, they are not completely eliminated or remedied. The flaws outlined above are inherent to metallic epoxy itself. The result, in our opinion, is that metallic epoxy will always be a substandard flooring system, and particularly in comparison with acid stain - and even other forms of decorative concrete, like polished concrete and polymer-modified decorative cement overlays.

We believe that, like all fads and trends, the newness of the metallic epoxy "craze" will eventually wear off. When it does, and homeowners start to encounter and be made more aware of this new flooring system's inadequacies in basement and garage settings, we also believe trending will quickly revert to acid-stained concrete flooring. Acid-stained concrete has consistently remained a unique, beautiful, durable and viable flooring system for concrete slabs, indoors and outside, for over a century now, since Frank Lloyd Wright introduced and popularized it in the early 1900's. There isn't any reason to believe that will change., and the failure of other flooring systems will only further increase its popularity.